Description

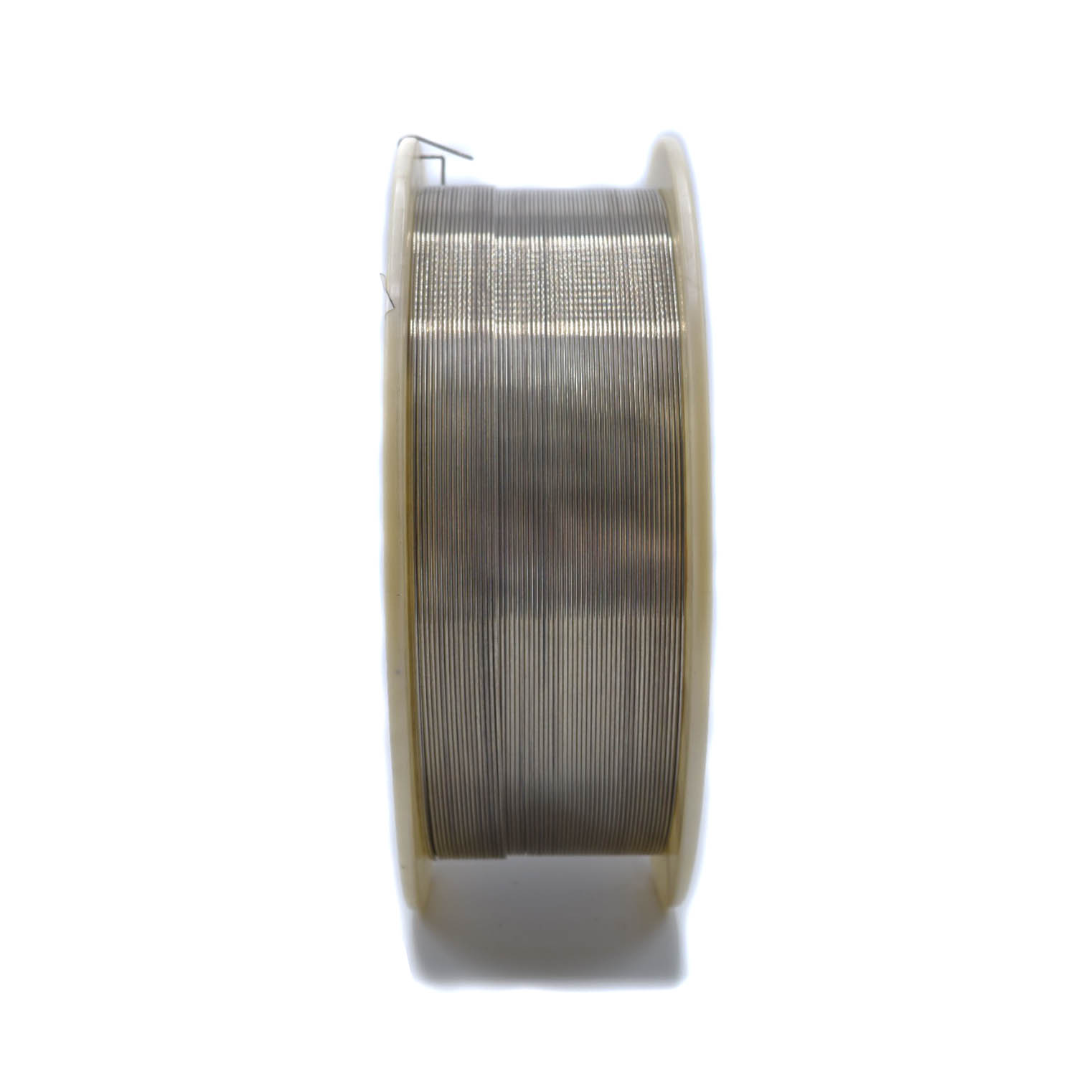

Metalink® 701 Ni-Al Bondcoat Wire

Nickel/Aluminum composite wire that provides the ultimate tensile strength bond coat for combustion wire and twin wire arc spraying. Manufactured by a proprietary process that covers a solid nickel core wire with a .015in sheath of aluminum which provides the proper exothermic reaction when sprayed with a combustion gun. Twin wire version employs an aluminum core with slightly more nickel content.

Advantages:

701 Ni-Al Bondcoat wire sprays at a higher speed compared to the currently available bond coat wires and gives an extremely homogeneous spray pattern. Also unlike wires with Nickel powder cores inside an Aluminum tube, this wire does not spit and sputter during application. Nickel powder core type wires tend to propel unmelted Nickel particles if the Aluminum sheath does not melt and provide the proper Exo-thermic reaction. This cannot happen with 701 Ni-Al Bondcoat wire as the solid Nickel wire cannot shoot out unless it is melted and atomized by the compressed air jet before it is sprayed. This ensures a high tensile strength bond that consistently tests at over 12,000psi – the best in the industry.

Recommended Spray Parameters

Parameters for Diablo Twin Wire Arc system: 200 Amps @ 27V with 50 to 70 psi Air Pressure utilizing high velocity air cap.

Parameters For 12M, 14M or equivalent torch: Set Oxygen Regulator at 301b and Acetylene Regulator at 151b. Flow Meter settings: 43 oxy, 39 act, 52 air (as indicated on most flow meters). Adjust feed settings so that wire is melting off approximately 1/4-3/8″ in front of the air cap. For other fuel gases, consult spool label.

Deposit Characteristics

• Typical Hardness HRB 75

• Bond Strength 9000 to 12,000-i-psi

• Deposit Rate 10 lbs /hr/100A

• Deposit Efficiency 70%

• Wire Coverage 0.9 oz/ft2 / m

Applications

• Bond Coat

• Dimensional Restoration

Surface Preparation Information Surface should be clean, white metal, with no oxides (rust), dirt, grease, or oil on the surface to be coated. Note: It is best not to handle surfaces after cleaning. Recommended method of preparation is, to grit blast with 24 mesh aluminum oxide, rough grind, or rough machine in a lathe.

Packaging information Part # Description

P701A 14ga (1.6mm) 33 LB LLWSpool

P701C .125 (3.2mm) 12.5# spool P701C .125 (3.2mm) 25# spool