Description

2 POUND KIT

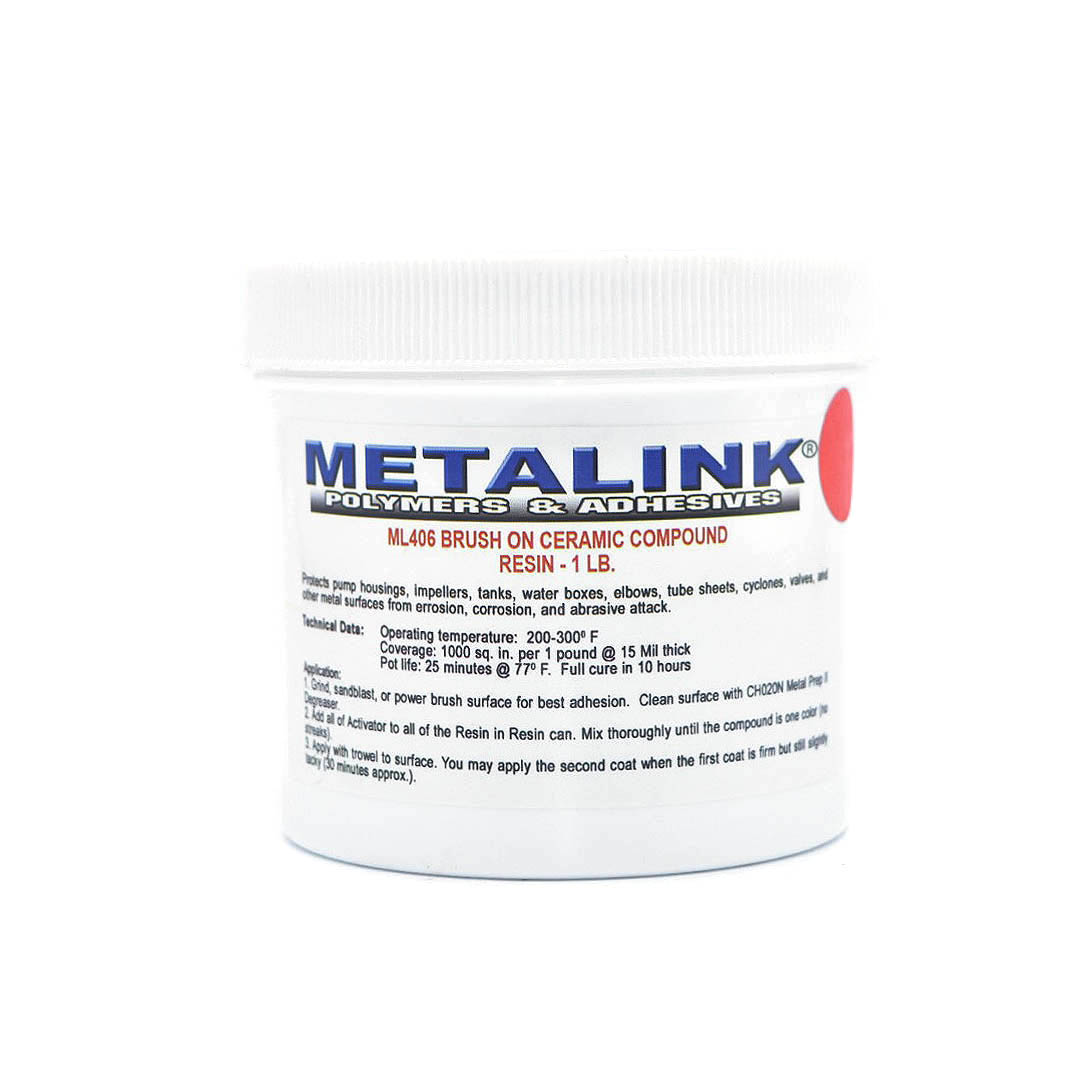

Metalink Brushable Ceramic is a two component, brushable, 100% solids (solvent free) high technology polymer formula, combined with diamond-hard ceramic fillers that provide an exceptionally tough surface for wear and corrosion areas. ML406 Brushable Ceramic offers a high gloss surface to eliminate sticking and turbulence. In addition to withstanding fine particle abrasive attack, it also protects against moderate corrosion and withstands temperatures up to 400ºF. ML406 Brushable Ceramic is available in two colors (red and blue), so that by alternating layers, you can more easily gauge wear.

TECHNICAL DATA:

Compressive Strength (ASTM-D-695-54)…………….21,000 psi

Tensile Strength (ASTM – D-638)…………………………4,800 psi

Operating Temperature (constant)…………………………..250ºF

Intermittent Temperature Fluctuations…………..up to 400ºF

Dielectric Strength…..500 volts/1 mil thickness (25 microns)

Hardness (Shore D)…………………………………………………96 D

Working Time (Pot Life) @ 77ºF………………………30 minutes

Cure Time @ 77ºF………………………………………………6 hours

Coverage…………………….3 sq. ft. per pound @ 30 mils thick

Mix Ratio-By Volume………………………..6 parts B to 1 Part A

By Weight………………………………………14 parts B to 1 Part A

APPLICATION INSTRUCTIONS:

1. Grind, sand, brush or grit-blast surface for best adhesion. Clean with CH020 Metal Prep Degreaser and wipe dry. In humid climates it is advisable to flame brush the surface to prevent flash rusting and to help the polymer to “wet out”. Apply ML900 Release Agent to any area you do not want the compound to adhere to.

2. Mix all Resin and all of Hardener thoroughly until uniform in color (no streaks). Apply fully mixed material to desired surface with the enclosed brush.

3. Working time is 25 minutes at room temperature. Material is hard in 6 hours and fully cures in 12 hours. The curing time may be shortened considerably by heating the surface to 150 degrees F. Second coats may be applied as soon as the first coat is firm (usually about 45 minutes).

TYPICAL APPLICATIONS:

Tube Sheets

Water Boxes

Pump Housings

Impellers

Tank Linings

Cyclones

Cort Nozzles

Chutes, Pipes, & Elbows

Hydroturbine Housings

Discharge Nozzles

Mixing Blades

Tap Water…………………………………………..E

Sea Water…………………………………………..E

15% Hydrochloric Acid…………………………E

20% Sulfuric Acid…………………………………E

10% Ammonia……………………………………..E

30% Caustic Soda…………………………………E

Gasoline……………………………………………..E

Xylene………………………………………………..E

Toluene………………………………………………G

Benzene……………………………………………..P

MEK…………………………………………………..G

50% Ethanol………………………………………..G

Methylene Chloride……………………………..P

E – Recommended for continuous immersion

G – Recommended for intermittent contact

P – Not recommended