WHAT IS T.S.A.?

While technically “TSA” is an abbreviation for “Thermal Sprayed Aluminum”, it has become a common acronym in today’s industry to describe the thermal spray application of a variety of sacrificial coatings for corrosion resistance, namely aluminum, zinc, and a combination of the two. Thermal Spray (commonly called Metallizing) is a process whereby a powdered or wire form of metal is melted by an energy source and propelled or sprayed onto the surface of another metal or structure for the purpose of corrosion control, wear resistance, traction, or to restore dimensions. Although there are many thermal spray processes available, the two most common and efficient methods of applying TSA coatings are Twin Wire Arc systems and Combustion Wire Fed (flame spray) systems.

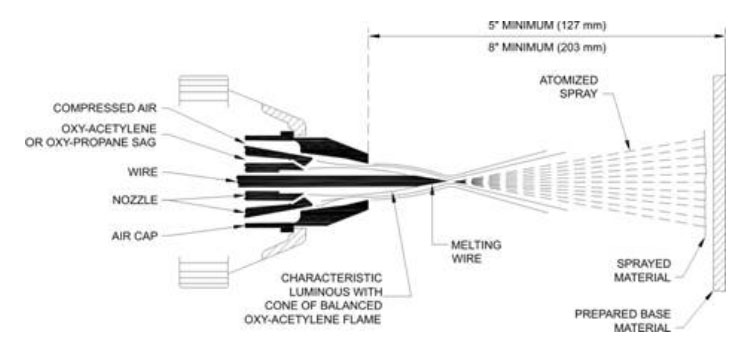

The Combustion Wire Fed System

(commonly called Flame Spray) is the oldest form of thermal spray processes. Very little has changed in the technology since its invention around 1910. Flame spray uses the chemical energy of oxygen and a variety of fuel gasses (acetylene, propane, propylene, Chemtane 2, natural gas, etc) to generate heat in the form of a flame at the tip or nozzle of a gun shaped torch. A single wire is introduced axially through the rear of the nozzle into the flame where it is melted and atomized. These particles are accelerated toward the substrate surface by the expanding gas flow and air jets. Compressed shop air is used to drive a turbine controlled gear box on the gun, which feeds the wire at a constant rate. The compressed air also serves to keep the gun within normal operating temperatures and to further atomize the molten spray metal and increase the velocity at which it is sprayed.

The Twin Wire Arc method

(commonly called Arc Spray) was originally developed at approximately the same time as the combustion methods, however, it did not gain popularity until the 1960’s. Since that time, there have been several technological advancements that have served to make Twin Wire Arc the method of choice for high volume applications of corrosion resistant metals. Twin Wire Arc systems work by pulling or pushing two electrically charged wires into a gun head assembly where they are bent to “arc out” on each other. Located immediately behind this hot plasma zone is a compressed air jet which blows across the arc area, atomizing and propelling the molten metal particles forward to coat the substrate. This method deposits a consistently atomized coating with high bond strengths and the highest deposition rates of any thermal spray method.

WHICH METHOD IS BEST?

Truth is, each method is particularly suited for its own specific applications. The Combustion Wire Fed systems are extremely portable and are easily operated on scaffolding at extended heights and in cramped quarters. They also exhibit quite a bit more deposit efficiency because the flame does not get most metals hot enough to gasify them to any degree. Over ninety percent of the wire stock actually gets deposited on the substrate. Many plants deem this process the safest for use in process areas where there is the potential for exposure to explosive gasses and spark hazards. On the other hand, the spray rates are quite a bit slower than Twin Wire Arc and the guns require much more maintenance and cleaning to avoid downtime and safety issues.

The Twin Wire Arc method deposits the maximum amount of metal in the shortest amount of time of any known thermal spray process. It’s ease of use and low maintenance requirements make it the application method of choice in many high volume shops where portability is not an issue. On the other hand, temperatures reached in the arc zone tend to gasify a portion of lower melting point metals and reduce the deposit efficiency somewhat (commonly in the 70% range). The gasified metals fall back out of the atmosphere in the form of metal dust in the immediate shop area, requiring good housekeeping practices to avoid health and safety hazards associated with metal dusts.

Most high volume TSA applicators actually employ both methods. They use the Twin Wire Arc method on large volume applications in a controlled shop environment, often sacrificing a bit of deposit efficiency for a huge amount of labor savings. The Combustion Wire Fed method is often employed as a back-up or auxiliary source, or on location where portability is a concern (such as a pipe rack or process tower at a petrochemical facility). Both methods have their specific uses and most TSA applicators use Twin Wire Arc and Combustion Wire Fed equipment interchangeably.

HOW DOES IT WORK?

Coating steel or other metal surfaces with a Offshore Platforms Commonly Protected by TSA less noble metal sets up a cathodic protection circuit. The metal surface becomes the cathode and the aluminum or zinc becomes the sacrificial anode. Moisture from the atmosphere, condensation, or submersion becomes the electrolyte to complete the electrochemical cell. Cathodic protection systems are commonly used to protect steel structures, pipelines, storage tanks, pier piles, oil platforms, ship hulls, etc. In some cases, cathodic protection can be an effective method of preventing stress corrosion cracking.

The TSA process deposits the less noble metal directly onto the surface of the metal to be protected as opposed to welding zinc or aluminum alloy anodes directly to pipe or structures. A freshly grit blasted surface prior to thermal spray coating ensures the electrical conductivity needed for proper current flow between the metals and ensures proper protection for the life of the coating. Thicker coatings provide longer life, based on the sacrificial wear rate of the metal (a common coating thickness for aluminum is approximately .015 inches or .38 mm).

Sacrificial thermal spray coatings provide much better corrosion resistance than paint or numerous other coatings, especially in cases where there is porosity or when the coating is breached. In seawater, the surrounding coating will even protect large cuts or breaches where steel is exposed. This makes TSA the coating of choice for corrosion under insulation (CUI) and areas where temperature extremes will not allow the use of common paints and sealers. Thermal sprayed Zinc is becoming a common replacement for hot-dip galvanized coatings. Especially for structures that are hard to dip or companies that want to control the zinc plating process in their own facility.

DOES IT WORK?

Aluminum, Zinc, and 85/15 Zinc/Aluminum coatings properly applied have proven effective over forty years or more. It is the coating of choice for corrosion under insulation or “CUI” at many large petrochemical facilities including Exxon/Mobil and Shell, who have both invested considerable time and effort in their CUI programs and research. Many governments and municipalities apply TSA coatings to bridges and infrastructure to prolong life and reduce repeated maintenance requirements. Thermal Spray zinc and aluminum coatings are progressively supplanting both painting and hot dip galvanizing for reasons of effectiveness, economics, and convenience. The coatings have predictable life, require but one single application, protect damaged areas cathodically, provide a degree of abrasion resistance, do not require drying, and are effective to nearly 1000 degrees F (538 C) . From the locks of the Panama Canal to oil rigs in the Gulf of Mexico, TSA coatings can be found protecting structures, piping, ships, towers, even concrete. They are even employed for decorative effects or non-skid applications such as steps and carrier decks.

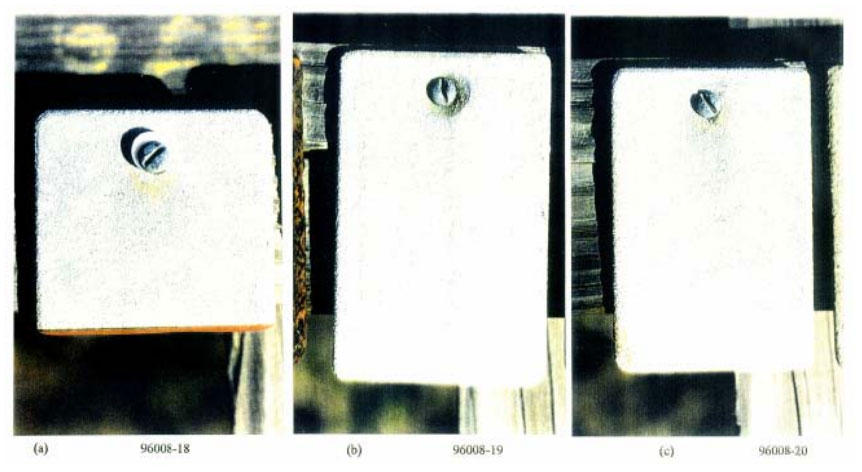

The below pictures indicate the supreme atmospheric corrosion resistance of thermal sprayed aluminum. Approximately .006 inches (.15mm) of thermal sprayed aluminum was applied to these carbon steel coupons nearly 58 years ago and affixed to a post located at Kure Beach Test Site in North Carolina. These pictures were taken after 44 years of atmospheric salt spray corrosion attack that only a beach can provide. As you can see, the coating is still intact and providing protection to the steel coupon. The testing agency that tracked results has long since disbanded, but the coupons are still weathering the storm.

Thermal spray coatings are in some respects, simpler to apply than paint or epoxy coatings. With a few hours training, any maintenance worker or coatings contractor can become skilled at the application of TSA coatings. Metalink® representatives can provide on-site training, manuals, and web-based curriculum to certify you to properly apply a wide variety of coatings, including all of the TSA varieties.

We provide both Twin Wire Arc and Combustion Wire Fed equipment and consumables to a wide variety of plants and contractors throughout the world. We not only sell and service our own brand equipment and wire, but we provide parts and service for other top brands as well, making us your preferred provider for all your thermal spray needs.

We are familiar with the training and procedure requirements of the military, D.O.T’s, State and Local governments, and numerous large chemical and petrochemical facilities and can train your personnel to meet those standards. We can even help you establish your own in-house training and procedures.

Come join our growing list of Metalink® Certified TSA Applicators today and begin reaping the benefits and protection of Thermal Sprayed Aluminum coatings.