Description

Metalink® P702 Stainless

316 stainless steel wire specifically designed for Twin Wire Arc spraying. Produces well-bonded coatings that are machinable and corrosion resistant. Typically used for dimensional restoration and corrosion resistant coatings. Deposits tend to shrink so deposit thickness is normally limited to .075 inches. Nominal Composition: 17Cr 12Ni 2Mn 1 Si Fe balance.

Applications

• Part Restoration

• Rams

• Food Industry Rolls

Surface Preparation Information Surface should be clean, white metal,with no oxides (rust), dirt, grease, or oilon the surface to be coated. Note: It is best not to handle surfaces after cleaning. Recommended method of preparation is, to grit blast with 24 mesh aluminum oxide, rough grind, or rough machine in a lathe.

Recommended Spray Parameters For use in a Diablo Twin Wire Arc System: 50 to 60psi Air Pressure, 27 to 29 volts, 200amps, 4 to 7″ standoff is a good starting point, but may be adjusted upwards for maximum deposition. Other settings may be required for alternate equipment.

Parameters Through Metalink 12M or 14M: 44 oxy, 39 act, 52 air, (as indicated on flowmeters)

Deposit Characteristics

Hardness 90 Rb (Harder when sprayed with combustion equipment)

Bond Strength 6750 psi

Deposit Efficiency 75%

Coverage 0.8oz/ft2/mil

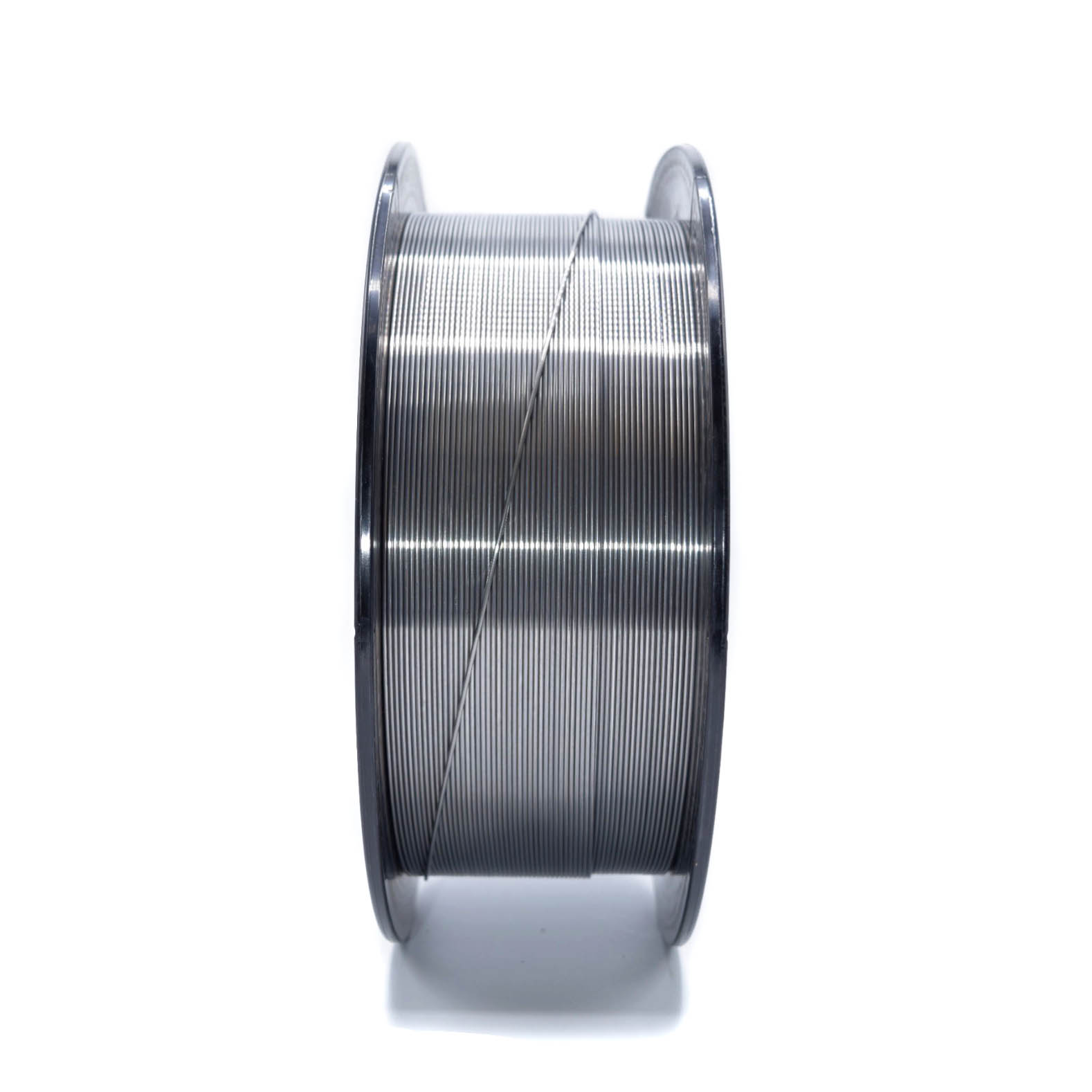

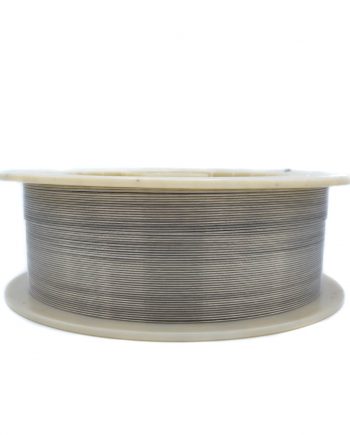

Packaging Information Part # Description

P702A – 14ga (1.6mm) 25# LLW Spool

P702C-25in (3.2mm) 60# Random Coils