Description

Metalink® P711 Arc Tungsten

46% by weight powdered Tungsten Carbide core wrapped in a 400 series stainless steel wire to produce extremely wear resistant coatings utilizing the twin wire arc process (no combustion applications). Suitable for high temperature and wear service environments such as steel mill conveyor and looper rolls.

Surface Preparation Information

Surface should be clean, white metal, with no oxides (rust), dirt, grease, or oil on the surface to be coated. Note: It is best not to handle surfaces after cleaning. Recommended method of prep-aration is to grit blast with 24 mesh aluminum oxide or hardened steel shot, rough grind, or rough machine in a lathe (lightly threaded preferable) in order to obtain the proper profile.

Recommended Spray Parameters

For use in a Diablo Twin Wire Arc System: 50 to 60psi Air Pres-sure, 27 to 29 volts, 200amps, 4 to 7″ standoff is a good starting point, but may be adjusted upwards for maximum deposition. Other settings may be required for alternate equipment.

Deposit Characteristics

Typical Hardness 65-70+Rc

Bond Strength 4 to 5000psi Deposit Efficiency 70% Coverage loz/ft2/mil

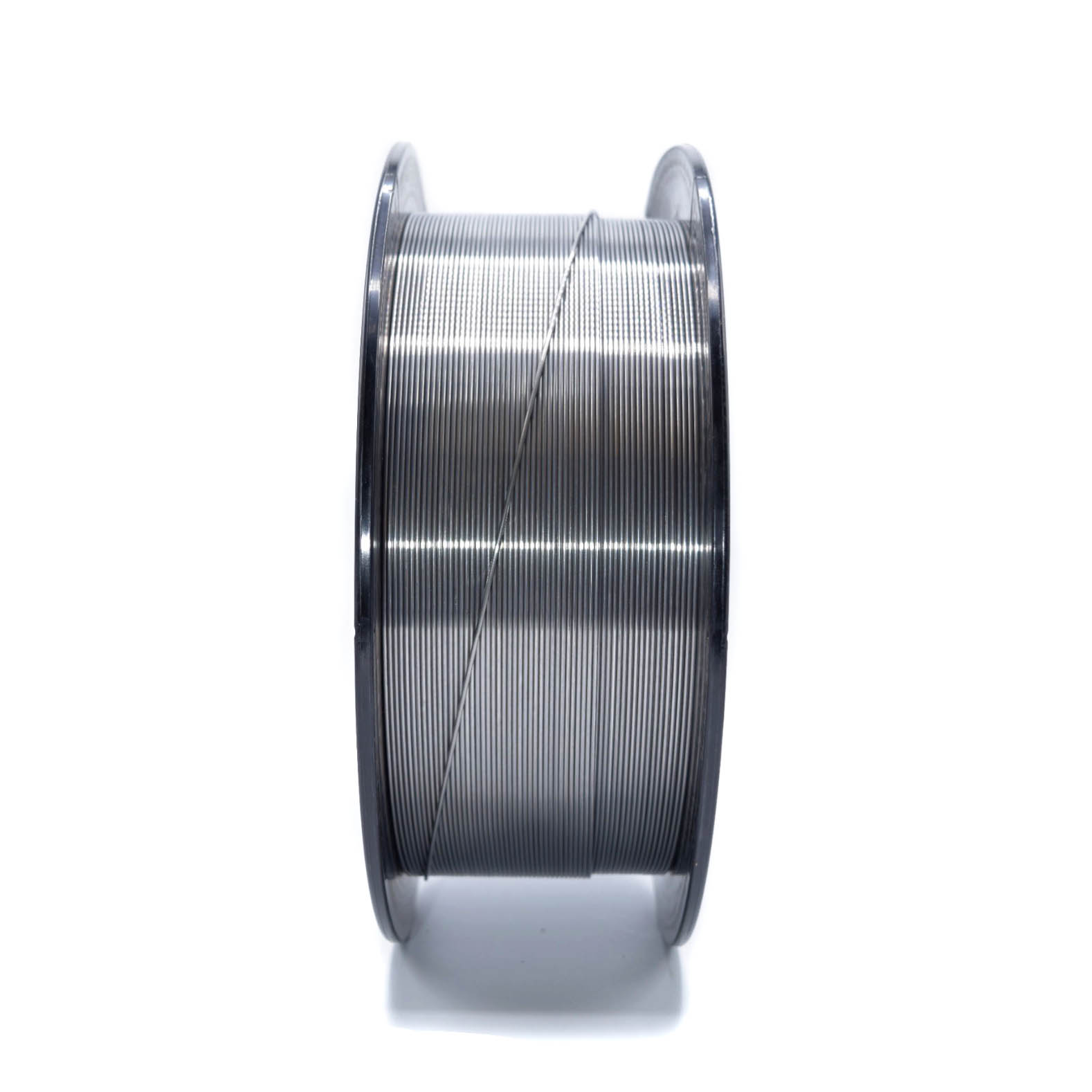

Packaging Information Part # Description

P71 IA – 14ga (1.6mm) 25# LLW Spools