Description

Technical questions and troubleshooting contact Matt Peterson at http://appliedmaintenance.com

Phone: 409-994-5751

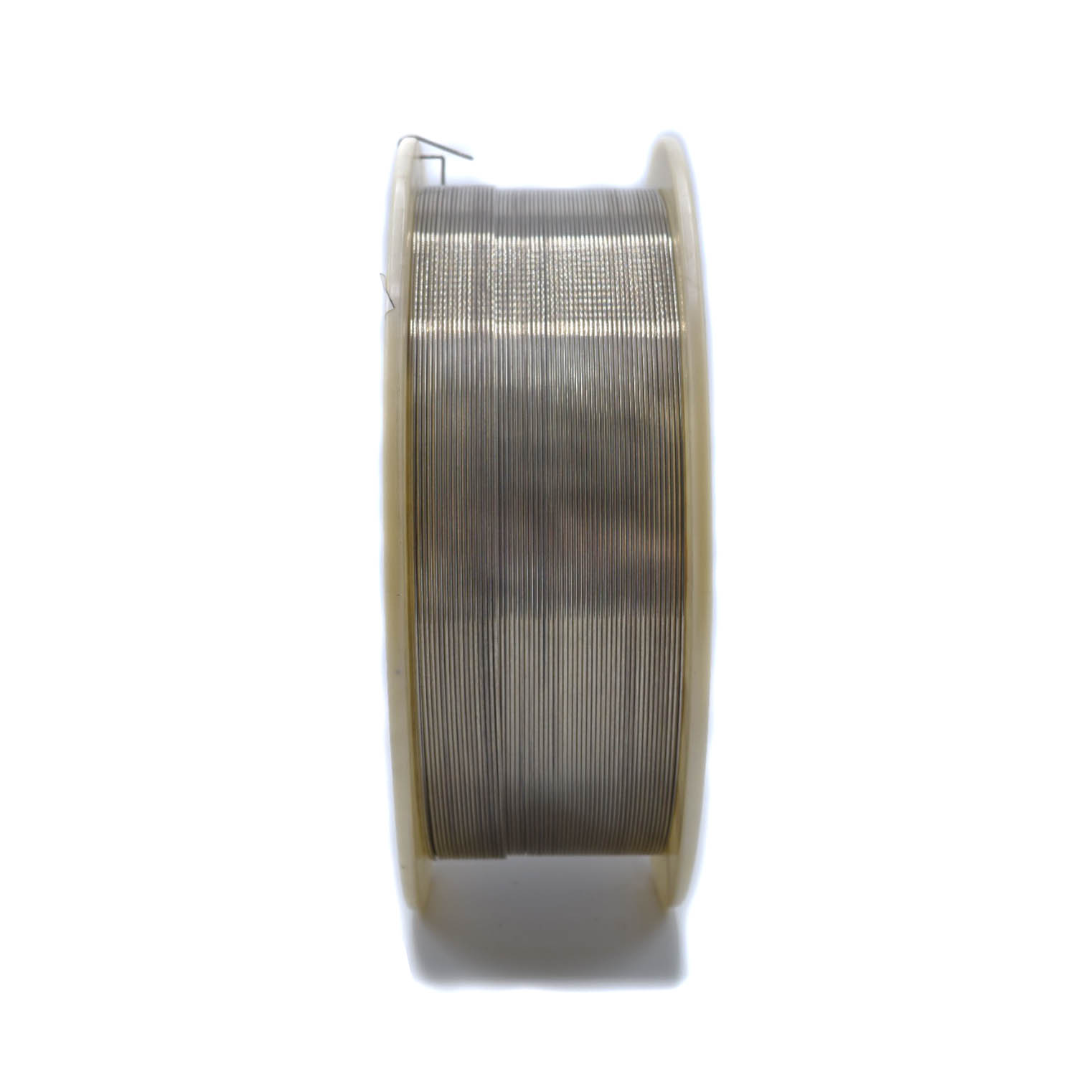

Metalink® 761 Ultra RollGrip Wire

Alloyed wire designed specifically to provide traction coatings on freshly machined steel mill rolls to prevent slippage and cobbles on cold starts. NickeliAluminide formula provides the ultimate tensile strength bond and protection from oxidation where poor plant water is an issue . Designed to wear off when roil is broken in. Available in both twin wire arc and combustion gun formulas.

Advantages

*Highest Bond Stength – Ultra Rollgripm consistently tests at the highest tensile strength bond available through flame spray wire feed guns. Will adhere to all types of rolls including those machined by ceramic inserts, but will not stick to any metal farther away than 18 inches. Safe to spray right at the lathe sight immedi-ately after turning. (No need to handle the roll twice),

*More Gripping Power – almost twice as coarse texture as lv1oly wire or powder spray produces. Better grip for those first few billets! *Sprays faster – metal can be applied between 40% and 60% faster than Nickel Powder cored wires. Moly wire, or powder_ Sig-nificant labor and fuel savings can be realized,

*Alternate Fuei Gas – with only a slight alteration in your gun, Ultra RollGrip TM will spray with Propane. Propylene, or Natural Gas (pressurized). Ultra RollGrip Is also available in .062 diameter spools for use in nearly any Twin Wire Arc system.

*Provides a corrosion resistant coating – coating is extremely corrosion resistant and will resist oxidation in storage and use,

*Smooth Spraying – No unmelted particles common to Nickel powder cored wires. No spits and sputters because the wire is designed to be melted outside of the air cap, greatly reducing over-heating and jamming of wire in the nozzle. Solid core provides an easier feed and no broken wire common to powder cored types,

*More Versatile – in addition to non-slip coatings, Ultra RollGripl” may be used to build up shafts, bearing fits, and even conveyor rolls (in place).

Recommended Spray Parameters

Parameters for Diablo Twin Wire Arc system: 200Amps @ 27V with 50 to 70 psi Air Pressure utilizing high velocity air cap, Parameters For 12M, 14M or equivalent torch: Set Oxygen Regulator at 301b and Acety-lene Regulator at 151b. Flow Meter settings: 43 oxy, 39 act, 52 air (as indi-cated on most flow meters). Adjust feed settings so that wire is melting off approxi-mately 1/4-318″ in front of the air cap. For other fuel gases, consult spool label.

Packaging Information Part #

P761A – 14ga (1.6mm) 25# LLWS

P761C – .125in (3.2mm) 12.5# spool

P761C – .125in (3.2mm) 25# spool

Deposit Characteristics

Typical Hardness 75Rb (Harder when sprayed w/ combustion equipment)

Bond Strength 12000psi

Deposit Efficiency 70%

Coverage 0.9oz/ft2/mil