Description

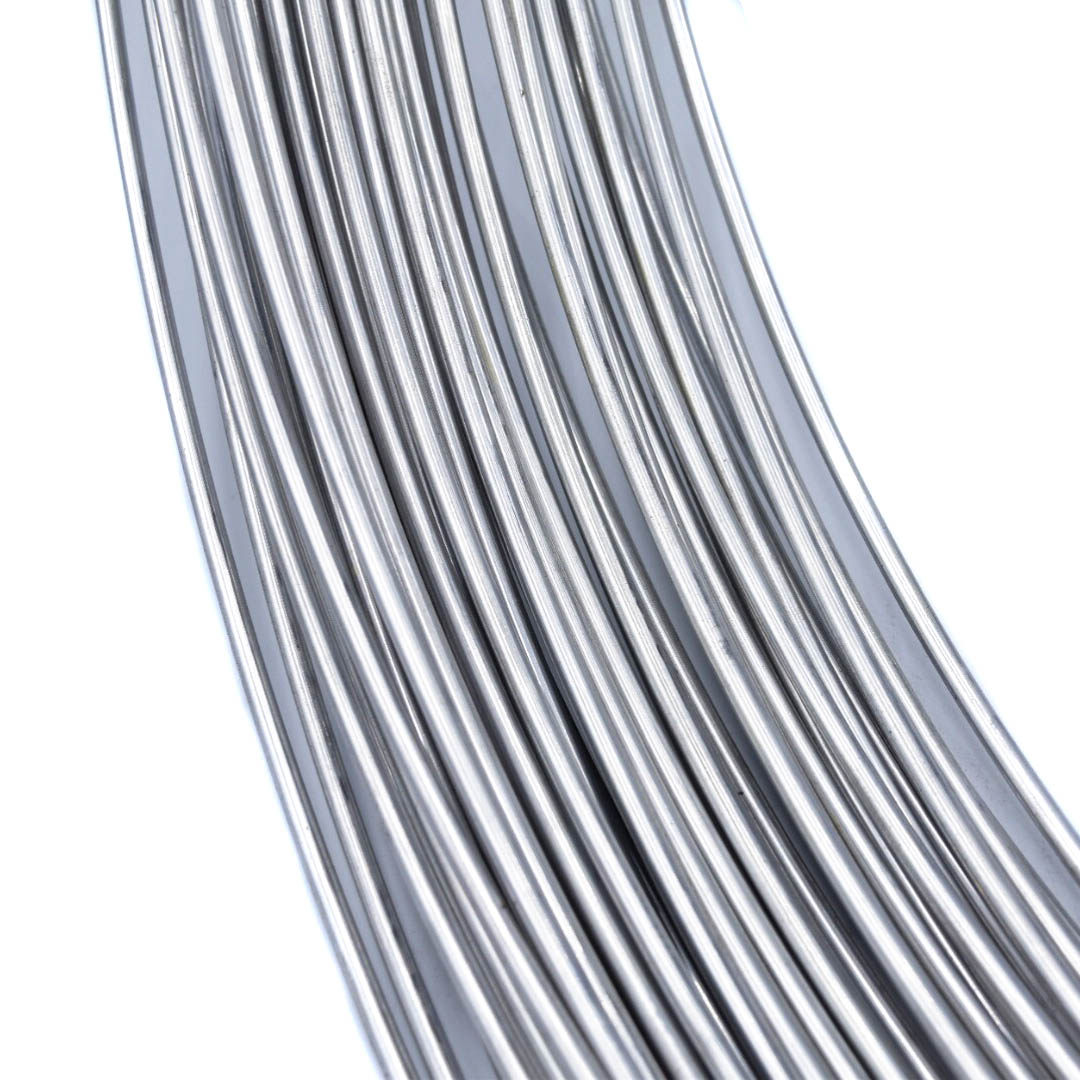

Metalink® 720 Ultra Moly

Wire Nearly pure Molybdenum wire for arc spraying and combustion gun applications. Produces coatings with excellent bond strength, superb wear resistance and good corrosion resistance. Particularly effective application where galling is a concern, such as piston rings, shift forks, and synchronizing rings. May also be used as a substitute for nickel bearing bond wires.

Advantages:

*No hazardous Nickel fumes – product is free of any carcinogenic compounds. Requires no special ventilation systems or breathing apparatus.

*Self-bonding alloy – will adhere to freshly machined metals without any bond coat

*Provides a textured surface to prevent slippage on rolling mill rolls during cold starts.

*Will spray through your existing wire gun with only minor setting adjustments.

*Provides a corrosion resistant coating to keep rolls from oxidizing during storage.

Surface Preparation Information

Surface should be clean, white metal, with no oxides (rust), dirt, grease, or oil on the surface to be coated. Note: It is best not to handle surfaces after cleaning. Recommended method of preparation is to grit blast with 24 mesh aluminum oxide or hardened steel shot, rough grind, or rough machine in a lathe (lightly threaded preferable) in order to obtain the proper profile.

Recommended Spray Parameters

For use in a Diablo Twin Wire Arc System: 50 to 60psi Air Pressure, 27 to 29 volts, 200amps, 4 to 7″ standoff is a good starting point, but may be adjusted upwards for maximum deposition. Other settings may be required for alternate equipment.

Parameters Through Metalink 12M or 14M: 44 oxy, 39 act, 52 air, (as indicated on flowmeters)

Deposit Characteristics

Typical Hardness 15 to 20Rc (Harder when sprayed w/ combustion equipment)

Bond Strength 7900psi

Deposit Efficiency 75%

Coverage 1.lozIft2Imil

Applications

-Wear Resistant Coatings

-Corrosion Resistance

-Anti Galling

-Bond Coats

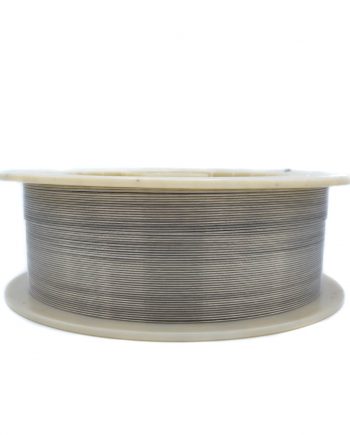

Packaging Information Part # Description

P720A – 14ga (1.6mm) 25# LLWS

P720C – .125in (3.2mm) 30#